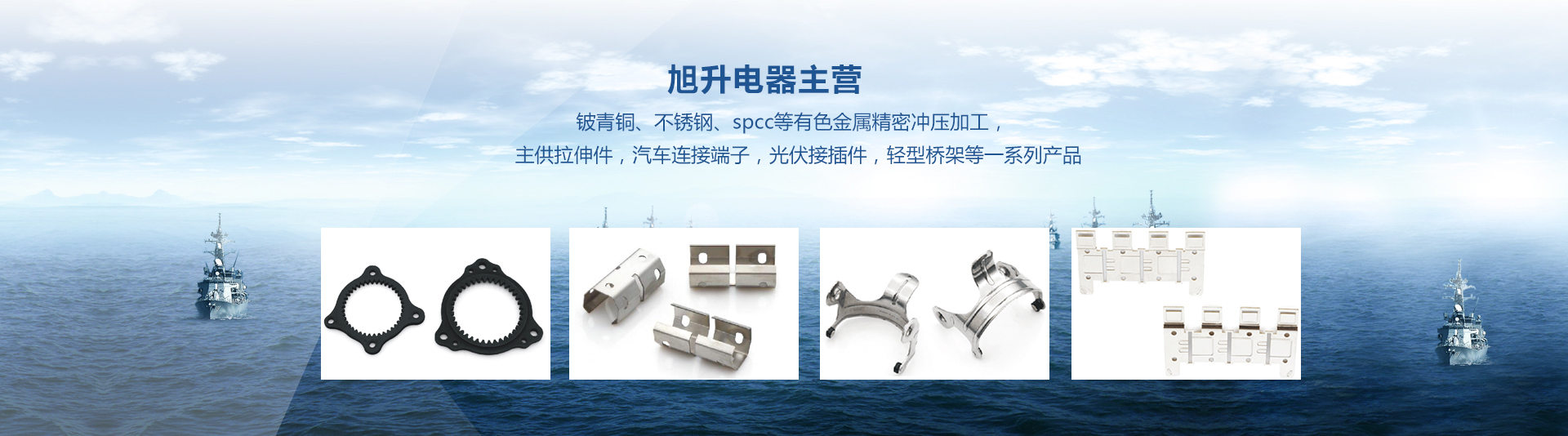

Connector RF coaxial connector manufacturers measure

With the rapid development of smart phones, the follow-up technological trend of mobile phone battery connector mainly presents miniaturization, low contact resistance, high current, high connection reliability and a new battery interface. High-current battery connector design is focused on how to reduce the contact resistance of the terminal, we can choose by the more conductive material, the structural design of the contact terminal to increase the positive force With the rapid development of smart phones, cell phone battery connector Subsequent technological trends are mainly represented by miniaturization, low contact resistance, high current, high connection reliability and a new battery interface.

The RF coaxial connector must correspond to the conductor on the crimping terminal of the heater to avoid a short circuit accident. Ceramic material not closely sintered, similar materials can not be used as additional insulation or reinforced insulation. The main reason is similar materials, often in the firing process, there are holes or bubbles in the material inside. The properties of the material can be compromised if it is put into wet or storage conditions. If similar materials are to be used for additional or reinforced insulation, the material should be tested for tightness by immersion in the red medicine water. Not because of the brittleness of the material. Brittleness and non-embarrassment are subjective judgments that generally pass the impact test and we can probably assume that they meet the requirements of mechanical strength.

China's connector market in the future if the prospects for the development if the very good, and with the global electronics manufacturing services continue to move to China, China is gradually becoming the world's connector manufacturing center, connector production and sales volume will continue to be steady increase. Although the connector is not the core of all kinds of products, but it is indeed an indispensable supporting role. No connector, all kinds of equipment can not be effectively connected, more can not form a whole, to play its effectiveness. In the foreseeable future, the market demand for connectors will continue to grow, while the relevant industries on the connector technology will also be higher and higher.

The importance of coaxial connectors in electronic systems is often underestimated. The use of cheap connectors tends to incur high costs in the end. Choosing the wrong connector creates a lot of hassle, such as inability to properly operate the system, rework and repair, and customer churn. This shows how important it is to choose the right connector for your electronic system. In fact, not only the electronic system connector can not be underestimated, all the devices used to the connector can not be ignored. The service life of a connector has become a measure of its reliability, so increasing the useful life of a connector has also become a design guide.

A good RF coaxial connector within the metal components should be able to maintain a certain temperature within the physical state does not change, thus ensuring its high performance. It is generally prescribed that it should withstand a maximum of 200 degrees and a minimum of 65 degrees below zero. The effect of humidity on RF coaxial connectors is the effect of water. Because water is corrosive to metal components, but also has a certain conductivity, can reduce the insulation, so the connector components of the material must be selected to minimize the impact of water. RF coaxial connectors should be capable of operating at least 96 hours at temperatures of approximately 90% -95% RH and 40 ° C. Salt spray is the water contains salt, it can produce chemical corrosion of metal components, affecting the electrical properties of RF coaxial connectors.